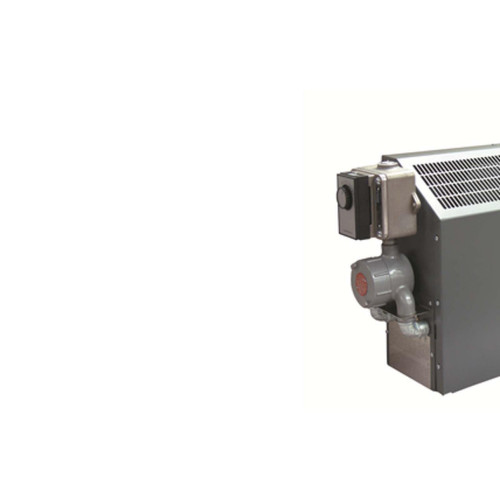

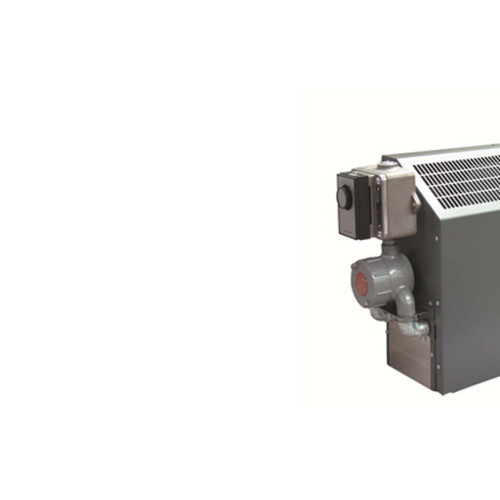

Markel FEP-7627-1RA Electric Hazardous Location Wall Convector, 7600 Watts, 277V/1Ph

Markel

$2,972.16

Usually Ships In 2-3 Weeks

Free ground shipping to the lower 48 states

- Product ID:

- Markel-FEP-7627-1RA

- UPC:

- 686334445306

- Weight:

- 85.00 (Lbs.)

- Ships By:

- Truck, Curbside, Back Of Truck

- Ships From:

- Tennessee - Factory Direct

Description:

Markel FEP-7627-1RA Electric Hazardous Location Wall Convector Features:

- Not cancelable, not returnable. Before purchasing please double check to confirm this item is correct for your application.

- Not cancelable, not returnable. Before purchasing please double check to confirm this item is correct for your application.

T-2A SERIES SINGLE PHASE, Class 1, Group B, C & D Division 1 & 2 280C / 536F

- Cabinet size 18 inches high X 9 inches deep.

- Bottom In - Top Out air flow.

- Wall mounting bracket supplied.

- Units cannot be operated in room ambients exceeding 104 degrees F (40 degrees C).

- Heavy duty 16 gauge steel with gray epoxy textured powder coated finish.

- 9 inch minimum clearance from bottom of heater to floor required.

- Stainless steel cartridge element inserted into Aluminum finned Copper sheath.

- Standard unit (without EPET thermostat or control section) is NEMA 4 rated.

- Made in U.S.A.

- California residents see Prop 65 Warnings.

- Bottom In - Top Out air flow.

- Wall mounting bracket supplied.

- Units cannot be operated in room ambients exceeding 104 degrees F (40 degrees C).

- Heavy duty 16 gauge steel with gray epoxy textured powder coated finish.

- 9 inch minimum clearance from bottom of heater to floor required.

- Stainless steel cartridge element inserted into Aluminum finned Copper sheath.

- Standard unit (without EPET thermostat or control section) is NEMA 4 rated.

- Made in U.S.A.

- California residents see Prop 65 Warnings.

RATINGS

Catalog Number: 04453002

Model Number: FEP-7627-1RA

Amp: 27.4

BTU: 25938

Agency Rating: ETL-CUS

Phase: 1

Voltage: 277

Wattage: 7600

Weight (Lbs): 85

Color: Gray

Model Number: FEP-7627-1RA

Amp: 27.4

BTU: 25938

Agency Rating: ETL-CUS

Phase: 1

Voltage: 277

Wattage: 7600

Weight (Lbs): 85

Color: Gray

HAZARDOUS LOCATION RATINGS DEFINITIONS

CLASS I:

Equipment does not have surface operating temperature in excess of the ignition temperature of the specific gas or vapor.

Equipment does not have surface operating temperature in excess of the ignition temperature of the specific gas or vapor.

Examples Include:

- Offshore and land based drilling rigs, petroleum exploration and testing facilities.

- Petroleum refineries, gasoline storage and dispensing areas.

- Industrial firms that use flammable liquids in dip tanks for parts cleaning or other operations.

- Petrochemical companies that manufacture chemicals from gas or oil.

- Dry cleaning facilities where vapors from cleaning fluids may be present.

- Aircraft hangers and fuel servicing areas.

- Utility gas plants and operations involving storage and handling of liquefied petroleum or natural gas.

- Petroleum refineries, gasoline storage and dispensing areas.

- Industrial firms that use flammable liquids in dip tanks for parts cleaning or other operations.

- Petrochemical companies that manufacture chemicals from gas or oil.

- Dry cleaning facilities where vapors from cleaning fluids may be present.

- Aircraft hangers and fuel servicing areas.

- Utility gas plants and operations involving storage and handling of liquefied petroleum or natural gas.

GROUP C:

Atmospheres such as but not limited to acetaldehyde, allyl alcohol, hydrogen sulfide, ethylene, carbon monoxide, or other gases or vapors of equivalent hazard.

Atmospheres such as but not limited to acetaldehyde, allyl alcohol, hydrogen sulfide, ethylene, carbon monoxide, or other gases or vapors of equivalent hazard.

GROUP D:

Atmospheres such as but not limited to acetone, alcohol, gasoline, lacquer solvent vapors, natural gas, propane or other gases or vapors of equivalent hazard.

Atmospheres such as but not limited to acetone, alcohol, gasoline, lacquer solvent vapors, natural gas, propane or other gases or vapors of equivalent hazard.

CLASS II:

Equipment does not have surface temperature greater than the ignition temperature of the specified dust.

Equipment does not have surface temperature greater than the ignition temperature of the specified dust.

Examples Include:

- Coal preparation plants and other carbon handling or processing areas.

- Grain elevators, flour and feed mills.

- Plants which manufacture, use or store Magnesium or Aluminum powders.

- Plants that have chemical or metallurgical processes.

- Producers of starch products or candy.

- Spice grinding plants, sugar plants and cocoa plants.

- Coal preparation plants and other carbon handling or processing areas.

- Grain elevators, flour and feed mills.

- Plants which manufacture, use or store Magnesium or Aluminum powders.

- Plants that have chemical or metallurgical processes.

- Producers of starch products or candy.

- Spice grinding plants, sugar plants and cocoa plants.

GROUP E:

Atmosphere containing combustible metal dust regardless of resistivity, or other combustible dust of similar hazard characteristics having resistivity of less than 10^5 OHM - Centimeter.

Atmosphere containing combustible metal dust regardless of resistivity, or other combustible dust of similar hazard characteristics having resistivity of less than 10^5 OHM - Centimeter.

GROUP F:

Atmosphere containing carbon black, charcoal, coal or coke dust.

Atmosphere containing carbon black, charcoal, coal or coke dust.

GROUP G:

Atmospheres containing combustible dust having resistivity of 10^5 OHM-Centimeter or greater.

Atmospheres containing combustible dust having resistivity of 10^5 OHM-Centimeter or greater.

DIVISION I:

A location in which ignitable concentrations of flammable material exist under normal operating conditions.

A location in which ignitable concentrations of flammable material exist under normal operating conditions.

DIVISION II:

Locations in which flammable materials will normally be confined within closed containers and escape only in the case of accidental rupture, breakdown or during maintenance operations. Any equipment approved for Division I is automatically also approved for Division II.

Locations in which flammable materials will normally be confined within closed containers and escape only in the case of accidental rupture, breakdown or during maintenance operations. Any equipment approved for Division I is automatically also approved for Division II.