Process Burners

Process burners are specialized combustion systems designed for industrial use, meticulously crafted to meet the demanding requirements of various processes. These burners are engineered to deliver optimal performance, ensuring efficient energy utilization, environmental compliance, and process reliability.

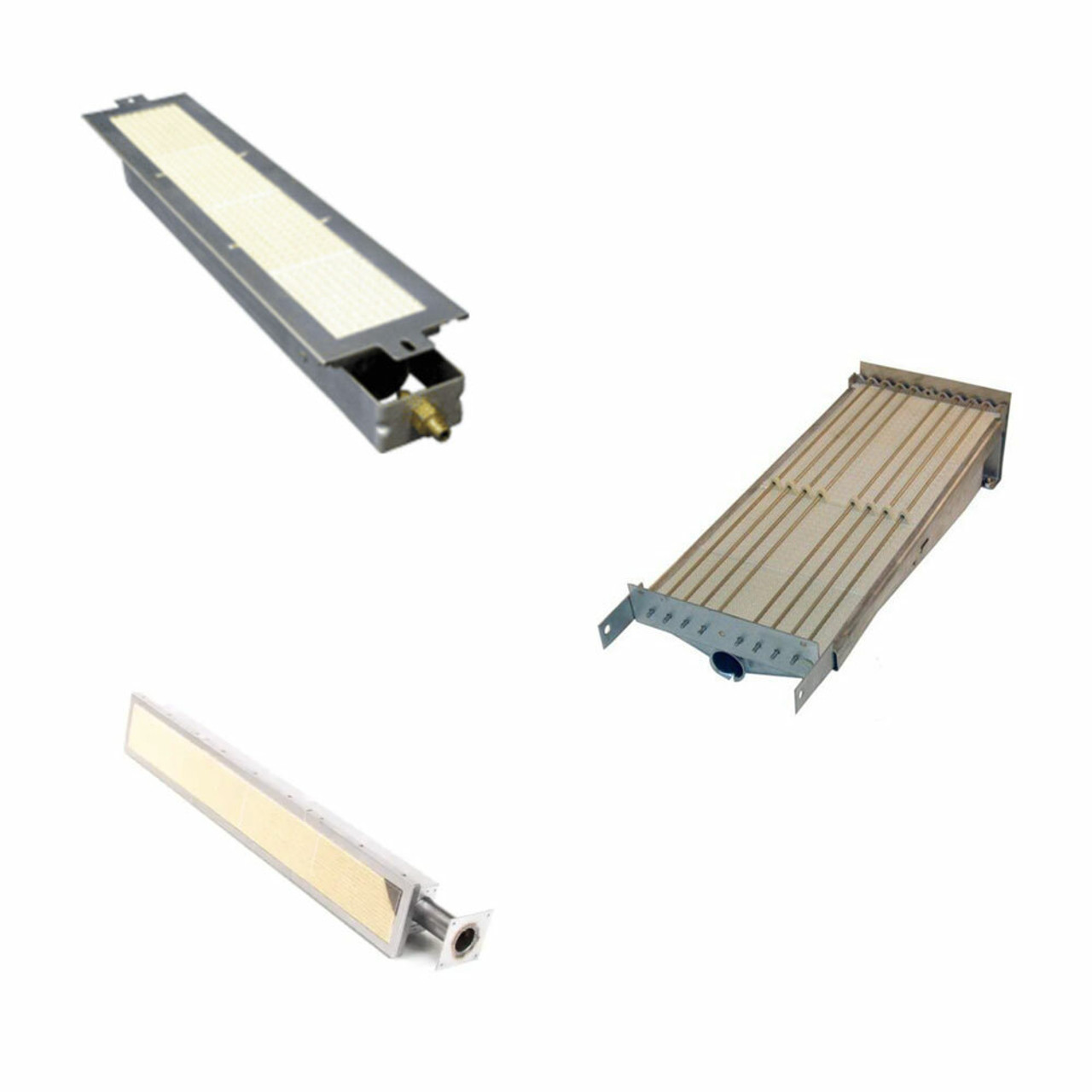

Ceramic Tile Gas Burners Used in a wide variety of industries, notably food cooking and process heating, ceramic tiles have a long and proven history as a reliable and economical burner solution for many applications.

Metal Fiber Gas Burners High-grade metal fiber burners are an effective heat solution for high-end appliances. Their unique textured surface creates an optimal radiant profile and their construction properties allow for a multitude of complex geometric designs. They can also operate at a wide combustion or temperature range.

Metal Foam Gas Burners Metal alloy foam burners are similar to metal fiber burners but offer advanced combustion efficiencies as well. The material is constructed of a 3D foam metal substrate and is best applied to cutting-edge combustion appliances.

Perforated Steel Gas Burners These burners are typically constructed from stainless steel sheets or tubes. They have a proven and reliable track record through the decades. Endless base material options provide a variety of solutions to balance port loading criteria, burner longevity, cost considerations and mechanical strength.

Wire Mesh Gas Burners Wire mesh burners are made from woven metal and share operating properties with ceramic tile burners. They offer a cost-effective, reliable solution for many mainstream combustion appliance applications.

Woven Ceramic Fabric (WCF) Gas Burners WCF burners are known for their simple, flexible fabric membrane. They are often found in pre-mix interior-combustion applications and offer unique design potential. WCF burners provide a wide range of BTU outputs, loading, evenness and flame stability.