Natural Gas / Propane Garage Or Workshop Heater Buying Guide

Posted by NorthStock, Inc. on Dec 26th 2012

Natural Gas / Propane Garage Or Workshop Heater Buying Guide

Fan Forced Natural Gas and Propane Unit Heaters for your Garage or Workshop.

Fan forced natural gas and propane unit heaters burn fuel in a heat exchanger to produce heat. Natural gas unit heaters are very common in populated areas that have natural gas piped throughout neighborhoods. Propane unit heaters are typically used in rural areas where natural gas is not available.

Operating Principle:

When there is a need for heating, the fuel from your natural gas line or propane tank flows through a gas valve inside the unit heater. A spark or pilot flame ignites the fuel and a flame is produced inside a heat exchanger. When the heat exchanger reaches a pre-set temperature, a fan turns on which blows space air through the warm heat exchanger. The air entering the heat exchanger absorbs the heat from the heat exchanger, resulting in a warmer discharge air temperature. As the fuel is burned, by-products of combustion leave the unit heater through a vent pipe also called a chimney.

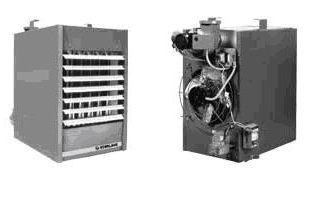

Common Gas or Propane Unit Heaters Used in Garages and Workshops

Benefits of fan forced gas or propane unit heaters in garages or workshops:

• Efficient.

• Powerful, fast self contained heat producers. They don't rely on a centralized boiler to supply heat.

• Low clearance requirements on low profile units.

• Most units have adjustable louvers to help direct warm air where you need it most.

• Durable. All unit casings are treated for corrosion resistance and finished with a baked-on, high solids paint.

• Huge range of sizes and styles to match the heater to your heating load. If selected properly, you don’t have to worry about under or over sizing.

• The fan can run in the summer without heat to help circulate air.

• Natural gas units are always ready to run. You don’t need to worry about replenishing your fuel supply.

Drawbacks of fan forced gas or propane unit heaters in garages or workshops:

• Gas fired units require more maintenance and service then other types of heaters.

• By-products of combustion require special attention. If the heater is not vented properly, dangerous fumes can enter your garage or workshop.

• Clearance requirements must be met. A flame is present. You must be sure combustible materials (fixed or airborne) stay away from the unit heater.

• Dirty, dusty or corrosive atmospheres require special attention.

• Fan forced units move large volumes of air which can kick up dust in your garage or workshop.

Unit Configurations:

Gas and propane unit heaters for garages and workshops blow air horizontally into the space. Adjustable louvers allow for vertical adjustment of airflow. Most major manufacturers also offer horizontal louvers that allow for side-to-side adjustment of airflow. Gas and propane unit heaters for garages and workshops can be broken down into several categories based on the venting type and heat exchanger design:

Venting Types:

Good: Gravity Vented

Due to its low cost and compact design, gravity vented propeller unit heaters are a good choice for some garages and workshops. The term gravity vented refers to a unit heater that vents naturally, without the assistance of a fan. A gravity vented unit uses the air in the garage or workshop for combustion. The warm by-products of combustion rise out of the unit heater through a flue pipe to the outdoors. A gravity vented unit is the least expensive style; however, you must be sure the following conditions exist:

1) Your garage or workshop can not be under a negative pressure. If your space is negative, the by-products of combustion will not vent properly and you will experience nuisance tripping from a safety switch that senses a blocked flue vent. Negative pressures occur when air is being exhausted from a space without any source of make-up air. Gravity vented units can be very sensitive to pressure changes. Sometimes a bathroom exhaust fan turning on can be enough to trip off a unit. If you have a gravity vented unit that is experiencing nuisance trip outs, you may want to install an aftermarket power venter that gets installed in the flue vent pipe to help push the by-products of combustion in the right direction.

2) Specific vent pipe routing is required. Gravity vented units operate on the principle that hot air rises. Vertical venting through the roof of your garage or workshop is preferred. Sidewall venting is more difficult. Venting through a roof can become more expensive since you need to completely weatherproof the hole in the roof. The manufacturer’s detailed installation instructions must be followed closely.

3) Since the air inside the heated space is being used for combustion, it is important that the atmosphere is clean. If you are comfortable lighting a match in your garage or workshop, then you should feel comfortable about running a gravity vented unit in your space. If there are any combustible dusts (woodworking shops) or fumes in your garage or workshop, choose a separated combustion design which is explained below.

Gravity Vented Unit – Vent pipe attaches to the top

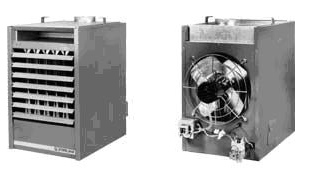

Better: Power Vented

A power vented unit is very similar to a gravity vented unit with the addition of an integral flue vent booster fan. On a call for heat, the booster fan turns on to ensure the by-products of combustion will be vented properly. Power vented units are the most popular type of gas and propane unit heater for garages and workshops. The booster fan allows for greater flexibility with flue pipe routing. Horizontal venting is very easy. In a garage or workshop, most venting is done through a sidewall to avoid costly roof modifications. Many of the major manufacturers are phasing out gravity vented units and are replacing them with power vented units as their entry level product.

Power Vented Unit – Vent pipe attaches to flue vent booster fan

Best: Separated Combustion

Separated combustion units are rapidly gaining in popularity. While traditional gravity and power vented units utilize space air for combustion, separated combustion units are sealed from the space. Separated combustion units for garages and workshops have 2 flue vent pipes. 1 flue vent pipe draws in air from the outdoors and 1 flue vent pipe exhausts the by-products of combustion back outside. This sealed combustion design eliminates you concerns about burning the air in your space. Separated combustion units are a must in your woodworking shop where fine dusts can ignite with an open flame. Separated combustion units are usually slightly more efficient since they do not use the heated air in your space for combustion.

The only drawback to a separated combustion unit in your garage or workshop is the 2nd vent pipe. A 2nd vent pipe requires a 2nd hole in your wall or roof. Most manufacturers offer concentric vent kits that allow the 2 vent pipes to join at a galvanized metal box on the interior of your garage or workshop. The box combines the 2 vent pipes on 1 end and diverts them into a pipe within a pipe on the discharge end. This allows you to only penetrate your wall or roof once. This also can make your unit more efficient as the warm flue exhaust warms the cold outside intake air.

Separated Combustion Unit – 2 pipes attach to unit

Heat Exchanger Designs:

Traditional natural gas and propane garage and workshop heaters are tall and narrow. Most manufacturers are transitioning towards the newer tubular heat exchanger design. Tubular heat exchanges are more flexible and resist cracking over time. This design also allows the unit to be wider and shorter which is necessary for most garages and workshops that do not have ample overhead clearance.

Standard natural gas and propane garage and workshop heaters come with aluminized steel heat exchangers. Aluminized steel is more then adequate for typical garage and workshop installations. The life expectancy for a natural gas or propane unit heater in a clean environment is 20+ years. If your application involves high humidity levels or mildly corrosive atmospheres, your natural gas or propane garage heater will last a lot longer if you upgrade to a stainless steel heat exchanger.

Options and Accessories:

Natural gas and propane garage and workshop heaters have several options and accessories to help meet your specific requirements. High CFM blowers, 2 stage units, wall mounted thermostats, air deflectors and vent caps are very common accessories used in garages and workshops. If you’re not sure what to order, call us and we will recommend a unit to meet your specific needs.

Installation Overview:

1) Suspend the unit heater using threaded rods or angle iron. Some of the low profile units include angle iron for mounting your unit directly to the ceiling.

2) Install natural gas or propane piping.

3) Install vent pipe.

4) Wire a low voltage wall thermostat to the heaters terminal strip.

5) Wire the high voltage power required to operate the heater. This is usually 120 volt power in garages and workshops.

Commonly Asked Questions:

1) How do I calculate the heating load for my garage or workshop?

ANSWER: Call us or use our simple heat load calculator. Do NOT fall for equipment that is advertised as “will heat up to 400 square feet”. Heating a 400 square foot insulated garage in Florida is a lot different then heating a 400 square foot un-insulated metal garage in Maine. 1 heater can not magically service both 400 square foot spaces. Call us; we are happy to run a detailed engineering calculation that will help you pick the perfect heater for your space. You do not want to undersize, and you do not want to oversize.

2) How do I control my natural gas or propane unit heater in my garage or workshop?

ANSWER: A wall mounted 24 volt thermostat is required. When there is a call for heat, the thermostat sends a signal to the natural gas or propane heater to turn on. Upgraded thermostats include a “fan” switch which allows you to operate the fan with no heat in the summer.

3) How do I determine how much heat a natural gas or propane unit heater will generate?

ANSWER: Natural gas and propane unit heaters for garages and workshops are listed by their fuel inputs. For example, a 100,000 BTUH unit will consume 100,000 BTU’s of fuel per hour. The actual heating output depends on the unit’s efficiency rating. If the unit is 80% efficient, the actual heat output will be 80,000 BTU’s per hour. Do not pick a heater based on the nominal size. Many people think this is the actual heat generated by the unit. They end up with a unit that is undersized.

4) What is the best location in my garage or workshop to install my natural gas or propane unit heater?

ANSWER: The natural gas or propane unit heater in your garage or workshop should be located in the coldest area, and it should be angled slightly so it blankets warm air across the coldest wall.

5) What is the best location to install a wall mounted thermostat in my garage or workshop?

ANSWER: The thermostat should be mounted in a location that represents a good average temperature in your garage or workshop. If it is located in a cold spot, it will falsely run the unit heater more then it should. If it is located in an area that receives direct sunlight, it will falsely run the unit heater less then it should. A well insulated interior wall is the best spot for the thermostat.

6) I have a natural gas unit heater that is 30 years old and in perfect condition. How do I convert this to propane?

ANSWER: Most manufacturers will only produce parts for equipment that is 20 years old. After 20 years, it is assumed the unit will be replaced with newer, more efficient technology. In some situations, you may be able to contact the manufacturer of the gas valve directly for an aftermarket conversion kit.

7) How can I compare the cost to operate natural gas, propane, oil and electric unit heaters?

ANSWER: Call us. We can calculate your heating load, and then convert that information into operating costs ($/hour) for various fuel types.

8) What is included in a natural gas to propane conversion kit?

ANSWER: Different fuel types operate at different flow rates and pressures. The springs and orifices inside the gas valve needs to modified to match the fuel type. On some equipment, the igniter also requires an upgrade.

9) How do I decide if a separated combustion natural gas or propane garage or workshop heater is required?

ANSWER: If you’re not comfortable lighting a match in your space, then you need a separated combustion unit so that there is no open flame being exposed to the heated space.

10) How do I vent my natural gas or propane garage or workshop heater?

ANSWER: You must carefully read the installation instructions for your specific heater. Manufacturers do a good job outlining common practices. Local codes may dictate venting requirements and override the manufacturer’s recommendations. It is not a good idea to buy your vent pipe in a “kit”. There are several types of vent pipe, and the inexpensive kits that are designed to fit all installations don’t always form a perfect seal. A kit that offers “flexibility” means there are a lot of expandable pieces and joints that need sealing. The fewer joints you have, the safer your system will be. Hang your heater in the best possible spot for comfortable heating. Draw a sketch of the venting required and bring it to you local plumbing or home goods store. They will know your local codes, and they will select the pieces in the longest lengths available. This saves a lot of extra joints that can be very dangerous if they are not sealed properly.